Nestled in the dynamic industrial hub of Delhi-NCR, Pyrocast India Pvt. Ltd. stands as a trusted name in closed-die aluminum forging, specializing in high-strength alloys. Our expertise spans Aluminium, Brass, Copper, and Non-Ferrous Forged Components, catering to industries that demand precision and durability.

At Pyrocast India, we are committed not only to quality but also to sustainability. By opting for electric heating ovens over traditional oil-fired furnaces, we actively contribute to a cleaner environment. This is just one of many steps in our journey toward becoming a green company, ensuring responsible manufacturing for a better tomorrow.

Discover our commitment to forging strength while shaping a sustainable future.

Let’s build something great together!

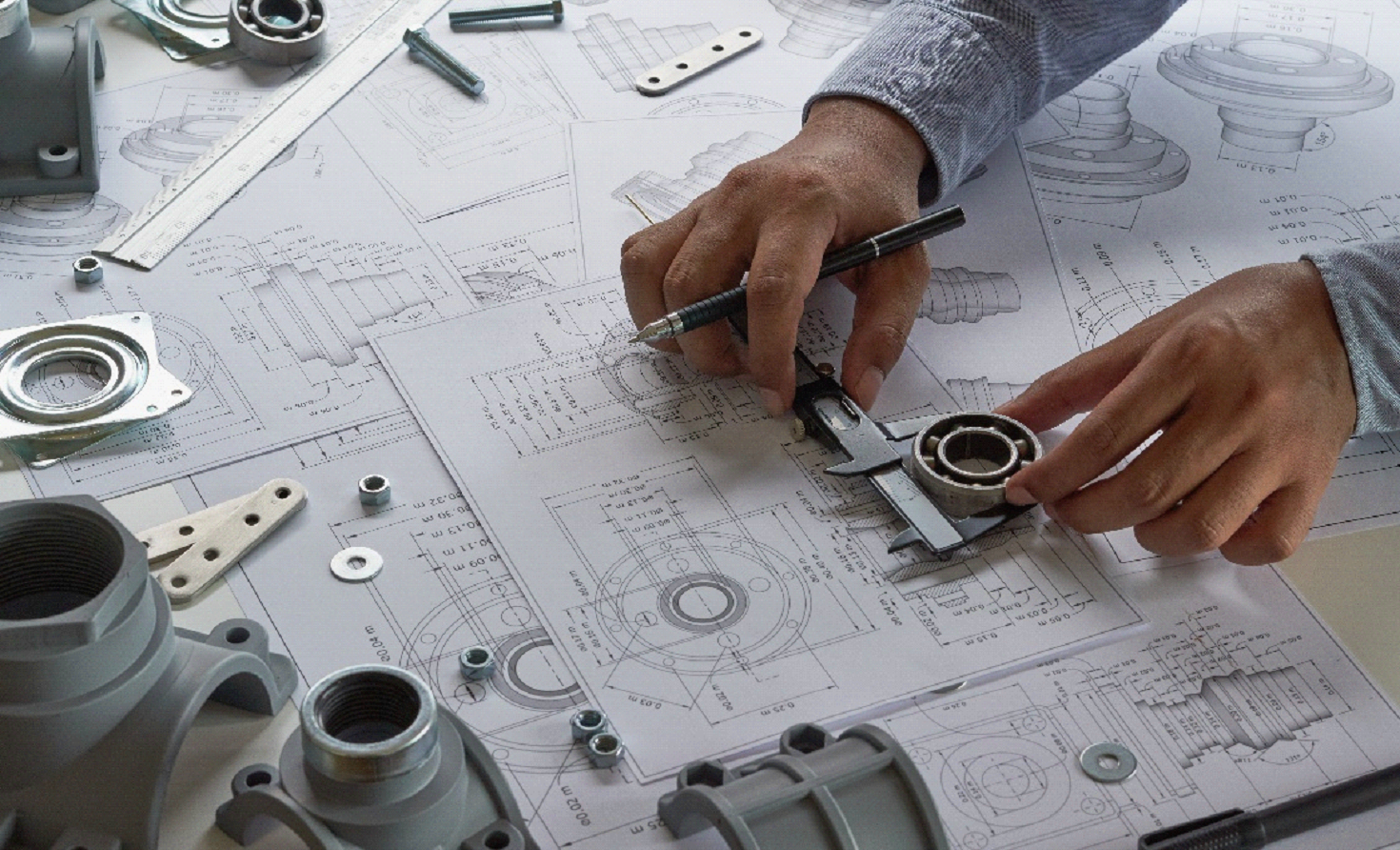

Precision Engineering

Eco-Friendly Manufacturing

In-House Machining & Quality Control

Cost-Effective Production

Versatility Across Industries

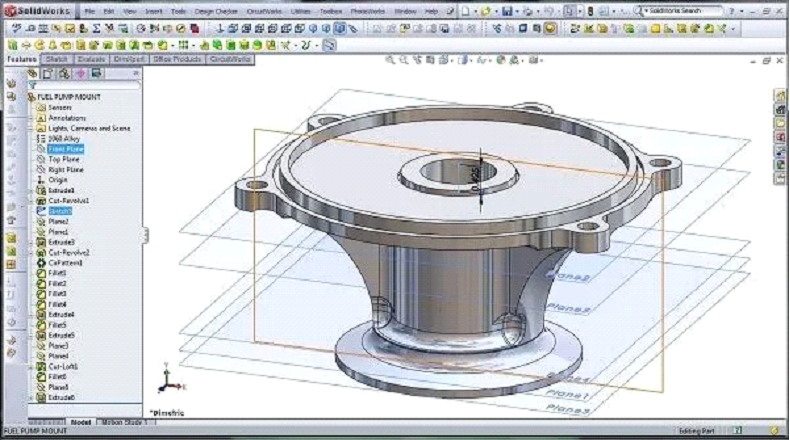

Custom Solutions & Innovation

At Pyrocast India Pvt. Ltd., we specialize in high-quality aluminum forging, offering precision-engineered components for industries such as automotive, aerospace, and industrial manufacturing. Our expertise extends beyond aluminum, encompassing brass, copper, and other non-ferrous forged products, ensuring durability, strength, and corrosion resistance. Driven by innovation and a commitment to excellence, we provide customized forging solutions tailored to industry-specific needs. Whether it's industrial forged products, automotive components, or high-strength alloys, our meticulous approach ensures reliability, performance, and long-term sustainability. At Pyrocast India, we don’t just forge metal— we forge trust, strength, and a greener future.

We manufacture precision-engineered aluminum forged components, catering to diverse sectors such as automotive, aerospace, industrial machinery, and heavy equipment. Each forging is crafted for maximum strength, durability, and performance.

We manufacture precision-engineered aluminum forged components, catering to diverse sectors such as automotive, aerospace, industrial machinery, and heavy equipment. Each forging is crafted for maximum strength, durability, and performance.

Our clients rely on us for high-quality, high-performance components essential to critical engineering applications. To meet these demands with precision and excellence, we adhere to the best engineering practices, ensuring superior reliability, durability, and innovation in every product.

We leverage cutting-edge operational strategies to optimize inventory management, ensuring that our clients benefit from cost-efficient solutions and receive the most competitive pricing for their requirements.

Our in-house manufacturing facilities are equipped to perform rigorous inspections, ensuring that all products adhere to precise manufacturing tolerances as per the agreed samples and guidelines.

Our internal design team goes above and beyond, integrating 3D model simulations to refine your innovative design, ensuring optimal size, weight, and performance tailored to your specifications.

As an innovative manufacturing company, we continuously enhance our production capabilities, expanding product depth, accelerating delivery times, and minimizing carbon footprints—benefiting both our operations and our clients.

Our team of highly skilled material testing engineers delivers Total Quality Assurance, providing precise materials analysis and testing for accurate predictive insights that drive enhanced product quality.

We prioritize eco-friendly practices by avoiding traditional oil-fired furnaces, making sustainability a core value. Our commitment to reducing emissions ensures responsible manufacturing for a cleaner future.

Products

Satisfied Clients

Countries Served